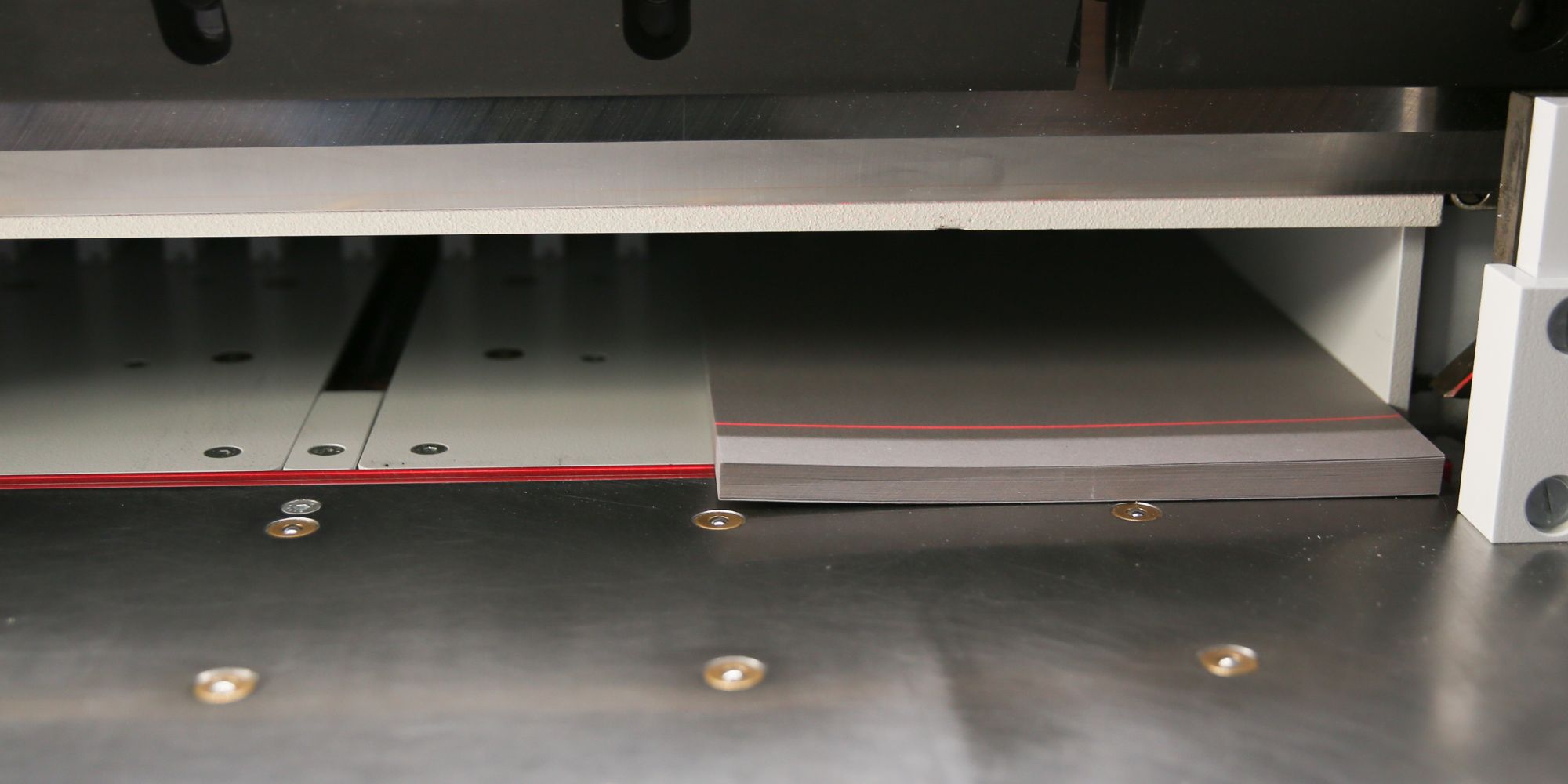

Guillotine cutting machine

Guillotine cutting machines have become an essential tool in various industries, providing efficient and precise cutting solutions. These machines are designed to handle a wide range of materials, from paper and cardboard to plastic and metal sheets. Investing in a high-quality guillotine machine can bring numerous benefits to your business, including increased precision, enhanced productivity, versatility, cost savings, and durability. In this article, we will explore these benefits in detail and provide maintenance tips to help prolong the lifespan of your guillotine cutting machine.

The Importance of Investing in a High-Quality Guillotine Cutting Machine

When it comes to cutting materials, precision and accuracy are crucial. A high-quality guillotine cutting machine offers superior precision, ensuring clean and straight cuts every time. This level of accuracy is essential, especially in industries such as printing, packaging, and signage, where even the slightest deviation can result in wastage and production delays. By investing in a reliable guillotine cutting machine, you can eliminate the risk of errors and achieve consistent, professional results.

Increased Precision and Accuracy

One of the primary advantages of a high-quality guillotine cutting machine is its ability to deliver precise and accurate cuts. These machines are equipped with advanced features such as laser guides and digital displays, allowing operators to make precise measurements and align materials with utmost accuracy. The sharp blades of a guillotine cutting machine ensure clean cuts without any frayed edges, providing a professional finish to your products. Whether you are cutting paper, cardboard, or even thick metal sheets, a high-quality guillotine machine will deliver precise results every time.

Another factor contributing to the precision of a cutting machine is its sturdy construction. High-quality machines are built with robust frames and components, minimizing vibrations and ensuring stability during the cutting process. This stability plays a crucial role in achieving accurate cuts, as even the slightest movement can affect the end result. By investing in a well-built guillotine cutting machine, you can have peace of mind knowing that your cuts will be precise and consistent.

Enhanced Productivity and Efficiency

In today’s fast-paced business environment, efficiency is key. A high-quality guillotine cutting machine can significantly enhance your productivity by streamlining the cutting process. These machines are designed to handle large volumes of materials, allowing you to cut multiple sheets at once. This not only saves time but also reduces labor costs, as fewer operators are required to handle the cutting tasks.

Additionally, advanced cutting machines come equipped with automatic features such as programmable cutting sequences and self-adjusting clamps. These features eliminate the need for manual adjustments and repetitive tasks, further improving efficiency. With a high-quality guillotine cutting machine, you can increase your production output without compromising on quality.

Versatility in Cutting Various Materials

One of the standout features of a high-quality guillotine cutting machine is its versatility. These machines can handle a wide range of materials, from thin paper to thick metal sheets. By investing in a guillotine cutting machine that suits your specific needs, you can expand the range of materials you can work with, opening up new possibilities for your business.

Different cutting techniques are available for various materials. For example, a guillotine cutting machine designed for paper may have a different blade configuration compared to one intended for metal cutting. High-quality machines offer flexibility in terms of blade options, allowing you to switch between different types of blades to suit your material requirements. This versatility ensures that you can adapt to changing customer demands and stay ahead of the competition.

Cost Savings in the Long Run

While the initial investment in a high-quality cutting machine may seem substantial, it is important to consider the long-term cost savings it can bring to your business. By investing in a reliable machine, you can reduce maintenance and repair costs that often arise from using low-quality equipment. High-quality guillotine cutting machines are built to last, with durable components that can withstand the rigors of daily use. This longevity translates to fewer breakdowns and lower repair expenses, ultimately saving you money in the long run.

Furthermore, a high-quality guillotine cutting machine can minimize material wastage. With precise cuts and accurate measurements, you can optimize material usage and reduce unnecessary scraps. This not only saves money but also contributes to a more sustainable and eco-friendly operation. By investing in a high-quality guillotine cutting machine, you are making a smart financial decision that will benefit your business for years to come.

Durability and Longevity of a High-Quality Guillotine Cutting Machine

A high-quality guillotine cutting machine is built to withstand the demands of heavy-duty cutting operations. These machines are constructed with durable materials and components that can endure the stresses of continuous use. The blades of a guillotine cutting machine are made from high-quality steel, ensuring sharpness and longevity. With proper care and maintenance, a well-built guillotine cutting machine can last for many years, providing reliable performance day after day.

To ensure the durability of your cutting machine, it is important to follow proper maintenance practices. Regular cleaning and lubrication of the blades and other moving parts are essential to prevent rust and ensure smooth operation. Additionally, scheduling routine inspections and servicing by qualified technicians can help identify potential issues before they escalate into major problems. By investing time and effort in maintaining your guillotine cutting machine, you can prolong its lifespan and maximize its value.

Maintenance Tips for Prolonging the Lifespan of Your Guillotine Cutting Machine

-

Clean the blades and cutting area regularly to remove debris and prevent build-up that can affect cutting performance.

-

Lubricate the moving parts of the machine, such as the blade hinges and clamp mechanisms, to ensure smooth operation.

-

Inspect the blades for signs of wear and tear, and replace them when necessary to maintain optimal cutting performance.

-

Keep the machine protected from dust and moisture by covering it when not in use.

-

Schedule routine maintenance and servicing by qualified technicians to address any potential issues and ensure the machine’s longevity.

By following these maintenance tips, you can extend the lifespan of your guillotine cutting machine and ensure consistent performance.

Conclusion: The Value of Investing in a High-Quality Guillotine Cutting Machine

Investing in a high-quality guillotine cutting machine is a wise decision for any business that requires precise and efficient cutting solutions. The benefits of such a machine, including increased precision, enhanced productivity, versatility, cost savings, and durability, are undeniable. By choosing a reliable machine and following proper maintenance practices, you can enjoy these benefits for years to come. So, why settle for anything less? Invest in a high-quality guillotine cutting machine today and take your business to new heights.

Contact us