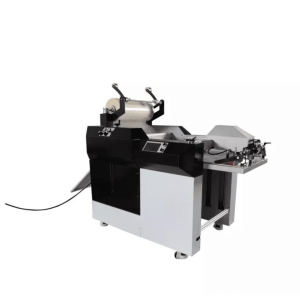

Automatic Laminator & Laminating Machine

Automatic laminators and laminating machines are one of the most essential pieces of equipment for any business. Whether you’re a small business looking for a reliable laminator for small projects or a large corporation needing a high quality, robust laminator for larger projects, it’s important to choose a machine that will meet your needs and budget.

The best automatic laminators and laminating machines combine the speed and efficiency of an automated process with the flexibility and convenience of manual lamination. By using these machines, you can quickly and easily produce professional-grade results. Automatic laminators and laminating machines are also great for customizing materials for short-run projects and for laminating sensitive documents like confidential contracts.

When choosing a laminating machine, you’ll want to consider a few things. First, you’ll need to determine the size and type of materials you’ll be laminating. This is important because different laminators and laminating machines are designed for different materials.

You’ll also want to consider the speed and consistency of the lamination process. Some of these are designed to produce a quick, one-time lamination. Others are designed to produce a consistent, high-quality lamination. Depending on your needs, you may need to invest in a machine that can perform both functions.

Finally, you’ll want to consider the cost . Machines range in price from relatively inexpensive models to more expensive models. It’s important to weigh your budget and needs against the cost of the machine to make sure you’re getting the best value for your money.

Automatic laminators and laminating machines are an essential part of any office or business. With the right machine, you’ll be able to quickly and easily produce professional-grade lamination results.

General Features:

- Ergonomically designed for easy machine operation

- High-speed feeding mechanism

- Single and double-sided thermal lamination available

- Heavy duty machines

- Automatic feeding & separation;

- Highly polished chrome roller with oil inside for better heating result;

- 6-15m/min laminating speed adjustable;

- Anti-curl and foil rewinder option.

- Safety features available

- Best value to money

- Easy to operate and maintain

- Widely used in schools, offices, shops, and other printing workshops.

FAQ Automatic Laminator & Laminating Machine

How does the Automatic Laminator work?

The Automatic Laminator is a machine that is used to laminate various types of materials such as paper, cards, photographs, and more. It works by applying a layer of protective film onto the surface of the material, enhancing its durability and appearance.

Here's a step-by-step explanation of how the Automatic Laminator works:

-

Material Placement: The operator places the material to be laminated onto the feeding tray or conveyor belt of the machine. This can include documents, cards, or any other type of item that requires lamination.

-

Adjusting Settings: The operator then adjusts the settings on the machine to specify the desired laminating temperature, speed, and thickness of the film. These settings can vary depending on the type of material and the desired outcome.

-

Film Loading: The laminator is equipped with rolls of laminating film. The operator loads the film onto the machine by inserting the film roll onto the designated spindle. The film is usually made of a thin layer of plastic, typically polyethylene or polyester, which has adhesive on one side.

-

Film Feeding: Once the film roll is loaded, the laminator automatically feeds the film onto the material that is being laminated. The film is guided over the material by a set of rollers or belts. The operator may need to ensure the material is properly aligned to prevent any issues during the lamination process.

-

Heating and Pressure: As the material and film pass through the laminator, heat is applied to activate the adhesive layer on the film. This heat melts the adhesive, allowing it to bond with the material. At the same time, pressure is applied to ensure proper adhesion and remove any air bubbles or wrinkles.

-

Cooling: After the lamination process, the laminated material continues through the machine, where it is cooled down. This helps to solidify the adhesive and ensure that the lamination is secure.

-

Trimming and Cutting: If necessary, the laminated material may be trimmed and cut to the desired size or shape using additional features on the laminator. This step helps to give the final product a clean and professional appearance.

What types of documents can the Automatic Laminator laminate?

The Automatic Laminator is capable of laminating a wide range of documents, making it a versatile tool for both personal and professional use. It can effectively laminate documents that are commonly used in various settings such as offices, schools, and homes.

Here are some examples of the types of documents that can be laminated using the Automatic Laminator:

-

ID Cards: The Automatic Laminator can laminate identification cards, ensuring their durability and protection against wear and tear. This is particularly useful in workplaces and educational institutions where ID cards are frequently used.

-

Certificates and Diplomas: Important certificates and diplomas can be preserved and enhanced by laminating them. By laminating these documents, their appearance is improved, and they become resistant to damage from handling, liquid spills, and fading.

-

Business Cards: Laminating business cards can add a professional touch to networking events and meetings. It not only protects the cards from getting creased or torn but also enhances their visual appeal, making a lasting impression on potential clients or partners.

-

Instruction Manuals: Laminating instruction manuals can greatly extend their lifespan. By protecting them from spills, smudges, and general wear and tear, laminated manuals remain readable and intact for a long time, ensuring the information they contain is always accessible.

-

Classroom Materials: Teachers can utilize the Automatic Laminator to laminate various classroom materials such as flashcards, educational posters, and activity sheets. Laminated materials are more durable, making them suitable for repeated use by students without the risk of damage.

-

Signs and Displays: Whether it's for a trade show booth, a retail store, or an event, laminating signs and displays can make them more eye-catching and resistant to wear. Laminated materials are sturdier and can withstand handling, making them ideal for high-traffic areas.

-

Menus and Price Lists: Restaurants and cafes can benefit from laminating their menus and price lists. Laminated menus are easy to clean and maintain, as they can be wiped with a damp cloth, ensuring that they remain presentable to customers.

Is the Automatic Laminator easy to operate?

Yes, the Automatic Laminator is indeed easy to operate. It is designed with user-friendliness in mind, making it suitable for both beginners and experienced users.

How does a Laminating Machine work?

A laminating machine is a device that is used to encase a document or paper in a protective layer of plastic. It is commonly used to preserve important documents, photographs, certificates, and other items that need to be protected from moisture, dirt, and wear and tear.

The process of laminating involves the use of heat and pressure to bond two layers of plastic film together, with the document or paper sandwiched in between. The machine typically consists of a heating element, two rollers, and a control panel.

Here is a step-by-step breakdown of how a laminating machine works:

-

Preparing the machine: Before starting the lamination process, the machine needs to be turned on and allowed to heat up. The control panel usually displays the desired temperature, which may vary depending on the thickness of the laminating pouch or film being used.

-

Placing the document: The document or paper that needs to be laminated is placed inside a laminating pouch or between two sheets of laminating film. The pouch or film is slightly larger than the document to allow for a sealed edge.

-

Feeding the pouch or film: The pouch or film, along with the document, is fed into the laminating machine through the opening at the front. The machine is designed to guide the pouch or film smoothly through the rollers, ensuring even heat distribution.

-

Heating and melting the film: As the pouch or film passes through the machine, it comes into contact with the heating element. The heat causes the plastic film to melt, activating the adhesive layer on one side.

-

Applying pressure: After the plastic film is melted, it enters the rollers of the laminating machine. The rollers apply pressure to squeeze out any air bubbles and ensure a strong bond between the layers of plastic and the document.

-

Cooling and curing: Once the laminated document has passed through the rollers, it continues to move towards the machine's exit. At this point, the plastic film starts to cool and solidify, creating a protective, durable seal around the document.

What are the benefits of using a Laminating Machine?

Using a laminating machine comes with several benefits that make it a valuable tool for both personal and professional use. Here are some of the key advantages:

-

Protection: One of the primary benefits of using a laminating machine is that it provides protection for important documents or materials. By encasing them in a layer of plastic, laminating helps to shield them from damage such as tears, spills, or smudges. For example, laminating important certificates, identification cards, or photographs can ensure their longevity and durability.

-

Durability: Laminated items are more resistant to wear and tear compared to non-laminated ones. The plastic layer adds strength and stiffness, making the documents or materials less prone to bending, creasing, or fading. This is particularly beneficial for frequently handled items like menus, ID cards, or instruction manuals.

-

Waterproofing: Lamination provides a waterproof seal, protecting the contents from moisture, spills, or humidity. This makes it ideal for items like maps, outdoor signs, or recipe cards that may be exposed to water or damp environments.

-

Enhancing Appearance: Laminating can significantly enhance the appearance of documents or materials. The glossy finish provided by the laminating machine gives a professional and polished look, making the content more attractive and visually appealing. This is particularly useful for marketing materials like brochures, flyers, or posters that need to capture attention and leave a lasting impression.

-

Easy Cleaning: Laminated surfaces are easy to clean and maintain. Dust or dirt can be easily wiped off without damaging the underlying content. This is advantageous for items like educational materials, reference sheets, or restaurant menus that require regular cleaning and hygiene maintenance.

-

Preservation: Laminating machine usage can play a crucial role in preserving important or sentimental items. By protecting them from aging, yellowing, or deterioration, laminating can help retain their original quality and appearance for years to come. Examples include preserving newspaper clippings, vintage photographs, or fragile documents.

-

Versatility: Laminating machines offer versatility in terms of the sizes and types of materials that can be laminated. They can handle various document sizes, ranging from small business cards to large posters, and can also laminate different materials like paper, cardstock, fabric, or even thin wood veneers.

Is it safe to use a Laminating Machine?

Yes, it is generally safe to use a laminating machine when following proper safety precautions. Laminating machines are designed to be user-friendly and have built-in safety features to prevent accidents. However, it is important to use caution and adhere to safety guidelines to ensure a safe laminating experience.

Here are some safety tips to keep in mind when using a laminating machine:

-

Read the instruction manual: Before using the laminating machine, carefully read and understand the manufacturer's instructions. This will help you become familiar with the machine's features and ensure its safe operation.

-

Choose a well-ventilated area: Laminating machines typically generate heat, so it is important to use them in a well-ventilated area to prevent overheating. Adequate ventilation will help dissipate any fumes emitted during the laminating process.

-

Use appropriate materials: Ensure you are using the correct laminating pouches or films designed for the machine you are using. Using inappropriate materials can cause jamming, overheating, or damage to the machine.

-

Allow the machine to warm up: Laminating machines require a warm-up period before they are ready for use. Follow the manufacturer's recommendations for the warm-up time to avoid any mishaps and ensure proper lamination.

-

Avoid overheating: Do not leave the laminating machine unattended for long periods or exceed the recommended operating time. Overheating can damage the machine and increase the risk of accidents.

-

Keep fingers away from hot surfaces: Laminating machines use heat to seal the laminating pouches. Exercise caution by keeping your fingers away from the hot rollers or areas to avoid burns or injuries.

-

Clean and maintain the machine regularly: Regular cleaning and maintenance will keep the laminating machine functioning optimally and reduce the risk of malfunctions or accidents. Follow the manufacturer's guidelines for cleaning and maintenance.